Types of Industrial Cabinet Door Handles

Industrial cabinet door handles are crucial components in various industries, ensuring secure access to equipment, tools, and materials. The selection of an appropriate handle depends on factors such as the application, environmental conditions, and required security level.

Lever Handles

Lever handles are commonly used in industrial settings due to their ease of operation and versatility. They are typically constructed from durable materials such as stainless steel, aluminum, or brass.

- Lever handles offer a comfortable grip, allowing for effortless opening and closing of cabinet doors, even with gloved hands.

- They are available in various styles, including straight, curved, and offset levers, providing design flexibility to match different cabinet aesthetics.

- Lever handles are often equipped with locking mechanisms, enhancing security and preventing unauthorized access.

- They are suitable for applications where frequent access is required, such as in workshops, laboratories, and manufacturing facilities.

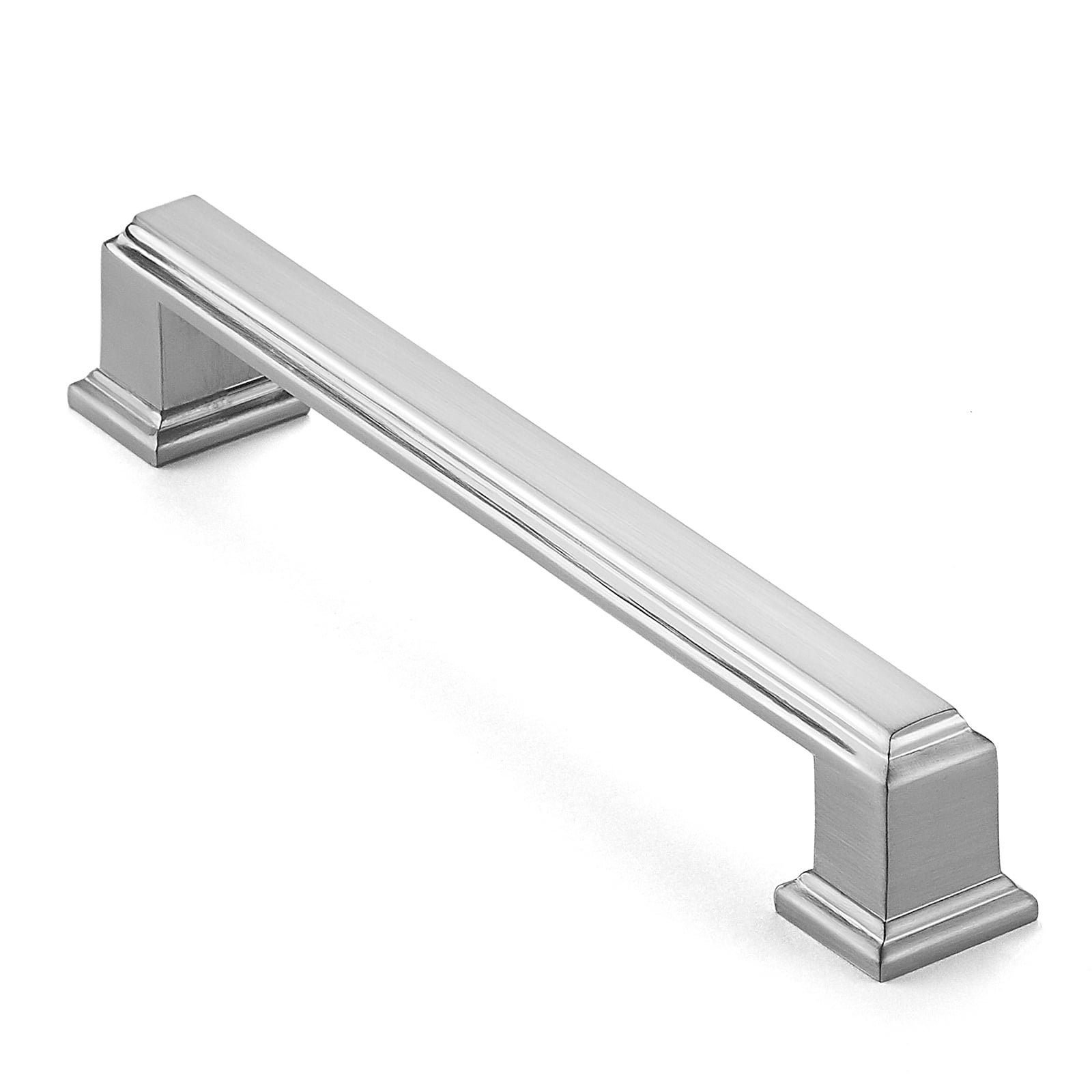

Pull Handles, Industrial cabinet door handles

Pull handles are designed for applications requiring a strong grip and forceful opening of cabinet doors.

- They are typically constructed from heavy-duty materials such as stainless steel or cast iron, ensuring durability and resistance to wear and tear.

- Pull handles are often used in industrial settings where heavy equipment or materials are stored, such as in warehouses, distribution centers, and manufacturing plants.

- They are available in various sizes and shapes, including straight, curved, and D-shaped handles, offering flexibility in design and functionality.

- Pull handles can be integrated with locking mechanisms for added security.

Knobs

Knobs are a common type of handle used in industrial cabinets, offering a simple and reliable solution for opening and closing doors.

- They are typically constructed from durable materials such as stainless steel, brass, or plastic, providing resistance to corrosion and wear.

- Knobs are available in various sizes and shapes, including round, square, and rectangular options, offering flexibility in design and functionality.

- They are often equipped with locking mechanisms, enhancing security and preventing unauthorized access.

- Knobs are suitable for applications where a simple and efficient handle is required, such as in control panels, electrical cabinets, and storage lockers.

T-Handles

T-handles are specifically designed for applications requiring a strong grip and leverage for opening cabinet doors.

- They are typically constructed from durable materials such as stainless steel or cast iron, ensuring durability and resistance to wear and tear.

- T-handles offer a comfortable and secure grip, allowing for easy opening of heavy cabinet doors.

- They are often used in industrial settings where heavy equipment or materials are stored, such as in warehouses, distribution centers, and manufacturing plants.

- T-handles are available in various sizes and lengths, offering flexibility in design and functionality.

Factors to Consider When Choosing Industrial Cabinet Door Handles

The selection of industrial cabinet door handles is a critical aspect of ensuring the functionality, security, and longevity of industrial equipment. Numerous factors influence the decision-making process, and understanding these factors is crucial for making informed choices that align with specific application requirements.

Durability

The durability of an industrial cabinet door handle is paramount, as it must withstand the rigors of frequent use, harsh environments, and potential abuse. Factors such as material selection, construction, and finish play a significant role in determining durability.

- Material: Handles made from robust materials like stainless steel, aluminum, or zinc-plated steel offer excellent resistance to corrosion, impact, and wear. These materials are commonly used in industrial settings due to their durability and ability to withstand harsh environments.

- Construction: The construction of the handle, including its design, thickness, and reinforcement, contributes to its durability. Handles with robust construction, such as those with reinforced mounting points and sturdy internal mechanisms, are more likely to withstand heavy use and potential impact.

- Finish: The finish of the handle protects it from corrosion, wear, and tear. Durable finishes, such as powder coating, electroplating, or anodizing, enhance the handle’s resistance to scratches, abrasions, and chemical attack. The choice of finish should consider the specific environmental conditions of the application.

Security

Security is a crucial consideration in industrial settings, where sensitive equipment, valuable materials, or confidential information may be stored. Industrial cabinet door handles play a vital role in securing these assets, and their security features are essential for safeguarding valuable contents.

- Locking Mechanisms: Handles equipped with robust locking mechanisms, such as key locks, combination locks, or electronic locks, provide enhanced security. These mechanisms deter unauthorized access and ensure the safety of valuable contents. The choice of locking mechanism depends on the level of security required and the specific application.

- Tamper Resistance: Industrial cabinet door handles should be designed to resist tampering and unauthorized access. Features such as concealed mounting points, hardened steel components, and tamper-proof locks enhance the handle’s tamper resistance, making it difficult for unauthorized individuals to gain access.

- Anti-theft Features: Some handles incorporate anti-theft features, such as break-resistant materials, concealed hinges, or anti-pry mechanisms, to deter theft and protect valuable assets. These features add an extra layer of security, making it more challenging for thieves to gain access to the cabinet.

Aesthetics

While functionality and durability are paramount in industrial settings, aesthetics also play a role in creating a professional and visually appealing environment. Handles that complement the overall design of the cabinet and the surrounding workspace contribute to a positive aesthetic experience.

- Style: Industrial cabinet door handles come in various styles, ranging from minimalist and modern to industrial and rugged. The choice of style should align with the overall design aesthetic of the cabinet and the surrounding environment.

- Finish: The finish of the handle, such as polished chrome, brushed nickel, or black oxide, can significantly impact the overall aesthetics. The choice of finish should complement the design of the cabinet and the surrounding environment.

- Color: The color of the handle should be considered, particularly in environments where color coordination is important. Handles available in a range of colors allow for customization and aesthetic integration with the surrounding environment.

Ergonomics

Ergonomics is essential for industrial cabinet door handles, as they are frequently used by workers. Handles designed with ergonomic principles in mind enhance comfort, reduce fatigue, and improve overall user experience.

- Grip: The grip of the handle should be comfortable and secure, allowing for easy opening and closing of the cabinet door. Handles with contoured grips, textured surfaces, or ergonomic shapes provide a comfortable and secure grip.

- Leverage: The leverage provided by the handle should be sufficient to open and close the cabinet door easily, even when heavy loads are present. Handles with extended levers or leverage points enhance ease of use and reduce effort required for opening and closing.

- Reach: The reach of the handle should be appropriate for the user’s height and physical capabilities. Handles with adjustable reach or extended levers allow for comfortable use by individuals of different heights and physical abilities.

Compliance with Industry Standards

Industrial cabinet door handles must comply with relevant industry standards and regulations to ensure safety, functionality, and compatibility with other equipment. Compliance with standards is essential for ensuring the handle’s performance, reliability, and safety in industrial settings.

- Safety Standards: Handles should meet safety standards, such as those related to strength, durability, and resistance to impact. These standards ensure that the handle can withstand the rigors of industrial use and prevent accidents or injuries.

- Compatibility Standards: Handles should be compatible with other equipment and components within the industrial setting. Compliance with compatibility standards ensures seamless integration with other systems and prevents issues related to mismatched components.

- Regulatory Compliance: Handles must comply with relevant regulations, such as those related to environmental protection, fire safety, or hazardous materials. Compliance with regulations ensures the handle’s safety and environmental responsibility.

Applications of Industrial Cabinet Door Handles

Industrial cabinet door handles are essential components in various industries, providing secure access and ergonomic functionality for diverse applications. Their selection depends on factors like environment, load capacity, and aesthetic requirements.

Manufacturing

Industrial cabinet door handles find extensive use in manufacturing facilities, ensuring secure access to critical equipment, tools, and materials.

- Tool and Equipment Cabinets: In manufacturing environments, tool cabinets often house specialized tools and equipment, requiring robust handles that can withstand heavy use. For example, a manufacturing facility producing heavy machinery might use large, lever-style handles on tool cabinets, providing ample leverage for easy opening even with gloved hands. These handles need to be durable and corrosion-resistant, given the potential for exposure to oil and other industrial fluids.

- Control Panels and Consoles: Industrial control panels and consoles often require access to complex machinery and systems. Handles for these applications need to be user-friendly and designed to minimize the risk of accidental operation. A manufacturing plant might use ergonomic, push-button handles on control panels to prevent accidental activation of critical machinery, ensuring operator safety.

- Material Storage Cabinets: Manufacturing facilities rely on secure storage for raw materials and components. Handles on these cabinets need to be robust and resistant to damage from heavy materials. A manufacturing facility storing heavy steel components might use heavy-duty, padlock-compatible handles on material storage cabinets to ensure secure storage and prevent unauthorized access.

Healthcare

Industrial cabinet door handles play a crucial role in healthcare facilities, where hygiene and safety are paramount.

- Medical Supply Cabinets: Hospitals and clinics require secure storage for medical supplies, ensuring sterility and proper inventory management. Handles on these cabinets should be easy to clean and disinfect. For example, a hospital might use antimicrobial, recessed handles on medical supply cabinets to prevent the spread of infections and maintain a clean environment. These handles are often made from materials like stainless steel, which is resistant to corrosion and easy to clean.

- Pharmaceutical Storage Cabinets: Pharmaceutical storage cabinets require secure access and precise temperature control. Handles for these applications should be resistant to corrosion and temperature fluctuations. A pharmaceutical company might use stainless steel handles with a high-polish finish on pharmaceutical storage cabinets, ensuring a clean, hygienic environment. These handles should be designed to resist corrosion from potential exposure to chemicals and humidity.

- Emergency Equipment Cabinets: Hospitals and clinics require quick access to emergency equipment. Handles for these applications should be easily accessible and user-friendly. For example, a hospital might use large, lever-style handles on emergency equipment cabinets, allowing for quick and easy access in critical situations. These handles are often designed with a bright color for easy identification in an emergency.

Data Centers

Data centers house sensitive equipment and require secure access and environmental control.

- Server Cabinets: Data centers rely on secure storage for servers and network equipment. Handles on these cabinets need to be robust and provide secure locking mechanisms. For example, a data center might use heavy-duty, keyed handles on server cabinets, ensuring secure access and preventing unauthorized entry. These handles are often designed to resist tampering and provide a high level of security.

- Network Equipment Cabinets: Network equipment cabinets require access for maintenance and troubleshooting. Handles for these applications should be user-friendly and provide secure access. A data center might use ergonomic, keyless handles on network equipment cabinets, allowing for easy access for technicians while maintaining security. These handles are often designed with features that allow for quick and easy unlocking.

- Power Distribution Cabinets: Data centers rely on secure access to power distribution systems. Handles for these applications need to be robust and provide a secure locking mechanism. For example, a data center might use heavy-duty, padlock-compatible handles on power distribution cabinets, ensuring secure access and preventing unauthorized manipulation of critical power equipment. These handles are often made from materials like stainless steel, which is resistant to corrosion and can withstand high temperatures.

Industrial cabinet door handles, with their stark lines and robust construction, often conceal a hidden world within. A world that, at times, requires access to the very core of the cabinet itself. If you find yourself needing to remove the center panel of such a door, this detailed guide can provide the necessary instructions.

Once the panel is removed, you’ll be able to see the inner workings of the cabinet, a glimpse into the heart of its functionality, much like removing the handle reveals the mechanism that secures the door itself.

The industrial cabinet door handles, with their rough hewn metal and utilitarian design, speak of a time when functionality reigned supreme. They seem to whisper tales of factories and workshops, of hands calloused from labor and tools forged in the heat of creation.

This rugged aesthetic can be perfectly complemented by the artmax 4 door cabinet , a piece that blends industrial strength with modern practicality. The artmax 4 door cabinet offers ample storage space, and when paired with these industrial door handles, it becomes a testament to the enduring beauty of functional design.